Innovation in a Pandemic: Local Heroes Design Ventilators

Written by Student Contributor Zachary Seburn – ESM Central High School

On March 11, 2020, the World Health Organization (WHO) officially designated the Coronavirus outbreak a global pandemic. As the number of cases in the United States skyrocketed, healthcare experts and government officials quickly realized the healthcare system was not readily equipped to handle this surge. Despite employing social distancing and public health guidelines to slow the rate of transmission, U.S. hospitals began reporting shortages in vital equipment needed for critically ill patients. With the virus reportedly causing inflammation of the lungs, pneumonia, acute respiratory distress syndrome (ARDS), and other hindrances to breathing, the shortage of ventilators soon gained national attention.

Commonly referred to as “breathing machines” or “life support”, ventilators are essentially mechanical lungs. These machines pump air into one’s lungs through a tube, allowing one to maintain oxygen flow while unable to breathe on their own. Prior to the pandemic, the United States had an estimate of 60,000 to 160,000 available ventilators. There was a broad range of estimated need for ventilators during the pandemic, ranging from several hundred thousand to over a million. No matter the estimate, one fact remained imminent: there would be a shortage of ventilators to face the pandemic.

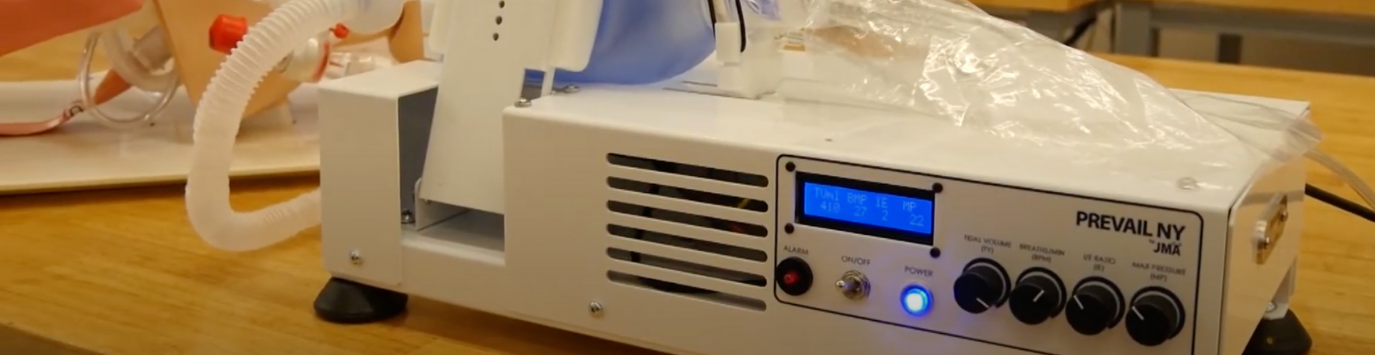

Acting quickly, a local collective sought to address this pressing issue. Dr. John Callahan, a local physician of internal medicine, discovered a design from the Massachusetts Institute of Technology (MIT) and worked with the institution to refine it. After learning MIT would not be manufacturing the device, Callahan reached out to Syracuse University, who then put him in contact with local telecommunications company JMA Wireless. After just ten days of consultation with Dr. Callahan, JMA engineers came up with the Pandemic Response Emergency Ventilation Assembled in Liverpool New York (PREVAIL NY).

The PREVAIL NYTM emergency ventilator utilizes an FDA-approved resuscitator kit known as a bag valve mask (BVM), which are in supply at hospitals. The device is controlled by an internal computer that mirrors the functionality of a full feature ventilator. JMA Wireless used off-the-shelf parts in the ventilator to keep production costs as low as $500. In pre-clinical trials, the emergency ventilator was able to successfully provide and restore ventilation in ARDS damaged lungs. The company has submitted the PREVAIL NYTM to the emergency use authorization program of the U.S. Food and Drug Administration. In addition to being able to produce the emergency ventilator locally if needed, the company has released the blueprints for manufacturers across the world.